Electro-Mechanical vs. Hydraulic & Pneumatic Actuators

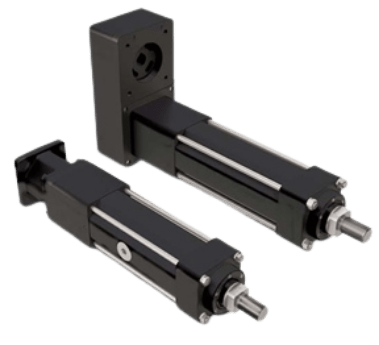

Electro-mechanical actuators are often a better choice than hydraulic or pneumatic alternatives with the advantages of simpler and smaller installation, easier control, lower energy costs, higher accuracy, less maintenance, less noise, and a cleaner, healthier environment. Check out our Electro-Mechanical actuator comparison below.

Electrical Actuators vs. Hydraulic & Pneumatic Cylinders

| Electro-Mechanical actuators comparison | |||

|---|---|---|---|

| Electrical Linear Actuators | Hydraulic Cylinders | Pneumatic Cylinders | |

| Installation | All electric operation requires simple wiring. | Requires expensive plumbing, filtering, pumps, etc. | Requires expensive plumbing, filtering, pumps, etc. |

| Accuracy | Very repeatable (to ± 0,013 mm) and rigid, multi-stop capabilities. | Requires expensive position sensing and precise electrohydraulic valving to implement, though tends to creep. | Difficult to achieve. Requires expensive position sensing and precise valving to implement, though tends to creep. |

| Control | Directly compatible with standard programmable controls, thus allowing easy automatic operation of complex motion sequences. | Requires electronic/fluid interfaces and exotic valve designs. Hysteresis, dead zone, supply pressure and temperature changes complicate control. | Inherently non-linear, compressible power source severely complicates servo control. |

| Speed | Smooth, variable speed from 0 to 2 m/s with controlled acceleration. | Difficult to control accurately. Varies with temperature and wear. Stick-slip can be a problem. | More susceptible to stick-slip and varying load, though well-suited for light high-speed applications. |

| Reliability | Repeatable, reproducible performance during the entire product life, while requiring very little maintenance. | Very contamination sensitive. Seals are prone to leak, so require regular maintenance. Reliable with diligent maintenance. | Very contamination sensitive. Air sources require proper filtration. Good reliability, but usually involves many system components. |

| Power | Up to 222 200 N | Virtually unlimited force. Most powerful. | Up to 25 000 N. Typically used below 6000 N. |

| Life expectancy | Up to millions of cycles at rated load. Easy to predict. | Dependent on design and seal wear, but usually good. | Dependent on design and seal wear, but usually good. |

| Environment | Standard models are rated for -30 to +70 °C. Inherently clean and energy efficient. | Temperature extremes can be a major problem, since seals are prone to leak. Waste disposal is increasingly problematic. | Temperature extremes can be a major problem, since seals are prone to leak. Air-borne oil can be a problem. |

| Load holding | Acme screw units are self-locking if power fails. Fail-safe brakes are available for ball screw and roller screw models. | Requires the use of complex backup safety devices. | Requires the use of complex backup safety devices. |

| Cost | Moderate initial cost, very low operating cost. | Components often cost less, but there are increases in installation and maintenance costs. Hydraulic power unit cost is high if not pre-existing. | Components often cost less, but there are increases in installation and maintenance costs. |